Entwodiksyon

This manual provides essential information for the proper installation, operation, maintenance, and troubleshooting of your new C·T·S replacement carburetor. This carburetor is designed to be a direct replacement for Kawasaki FG230 engines, corresponding to OEM part numbers 15003-2475 and 15003-2441. Please read this manual thoroughly before attempting any installation or service to ensure safe and effective use.

Enfòmasyon enpòtan sou sekirite: Always wear appropriate personal protective equipment (PPE) such as safety glasses and gloves when working with fuel systems. Ensure the engine is cool and disconnected from its power source (e.g., spark plug wire removed) before beginning any work. Work in a well-ventilated area and keep fire extinguishers nearby when handling fuel.

Pwodwi souview ak Konpatibilite

The C·T·S Carburetor (Model: CB-345) is a high-quality replacement component for the fuel system of Kawasaki FG230 engines. It is engineered to meet or exceed the specifications of the original equipment manufacturer (OEM) parts 15003-2475 and 15003-2441, ensuring proper fit and function.

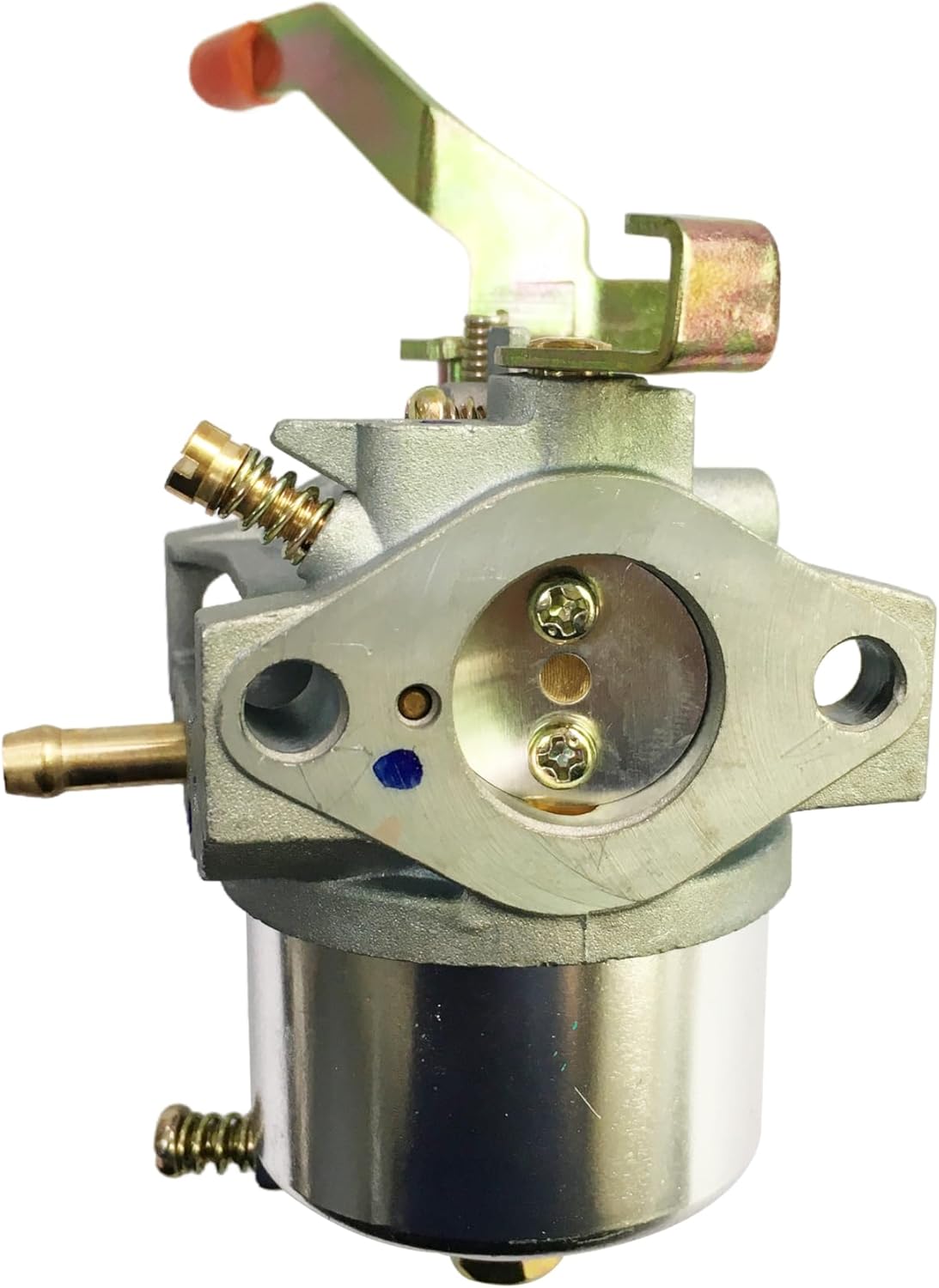

Figi 1: Devan view of the carburetor, showing the main body, fuel inlet, and the red-tipped choke/throttle lever.

Figi 2: Side view of the carburetor, highlighting the air intake port and mounting holes.

Figi 3: Angle view of the carburetor, showing the fuel bowl and adjustment screws.

Figi 4: Top view of the carburetor, illustrating the linkage and spring mechanisms.

Figi 5: Alternate top view, providing a different perspective on the carburetor's upper components.

Figi 6: Anba view of the carburetor, showing the fuel bowl and its drain screw.

Figi 7: Close-up of the fuel bowl, highlighting the bolt with an '8.8' marking, indicating a specific grade or torque specification.

Enstalasyon ak Enstalasyon

Proper installation is crucial for the carburetor's performance and longevity. If you are unsure about any step, it is recommended to consult a qualified technician or refer to your engine's specific service manual.

Zouti ak Materyèl (Tipik):

- Socket/Wrench set

- Set tournevis

- Pens

- Liy gaz clamps

- New gaskets (if not included with carburetor)

- Netwaye ranyon

- Fuel-safe container for draining old fuel

- Linèt sekirite ak gan

Etap enstalasyon:

- Preparasyon: Ensure the engine is off and cool. Disconnect the spark plug wire to prevent accidental starting. Place a fuel-safe container under the carburetor to catch any spilled fuel.

- Fuel Line Disconnection: Locate the fuel line connected to the old carburetor. Use pliers or a clamp to pinch the fuel line to prevent fuel flow, then carefully disconnect it from the carburetor. Drain any remaining fuel from the carburetor into the container.

- Linkage Disconnection: Carefully disconnect any throttle and choke linkages or springs attached to the old carburetor. Note their positions for reassembly.

- Removal of Old Carburetor: Devise boulon oswa nwa montaj ki kenbe ansyen karburatè a nan manifòl motè a. Retire ansyen karburatè a ak tout ansyen garnitur yo.

- Preparasyon sifas: Clean the mounting surface on the engine manifold to ensure a good seal. Remove any old gasket material.

- Plasman Joint: Place new gaskets (if applicable) onto the mounting studs or surface.

- New Carburetor Installation: Carefully position the new C·T·S carburetor onto the mounting studs, ensuring the gaskets are properly aligned. Secure it with the mounting bolts/nuts, tightening them evenly to prevent warping.

- Linkage Reconnection: Reconnect all throttle and choke linkages and springs to the new carburetor. Ensure they move freely and operate correctly.

- Fuel Line Reconnection: Reconnect the fuel line to the new carburetor's fuel inlet. Remove any clamps from the fuel line.

- Tèks final yo: Double-check all connections, ensuring they are secure. Inspect for any potential fuel leaks. Reconnect the spark plug wire.

Enstriksyon Operasyon

After installation, the engine should be ready to start. Minor adjustments may be necessary for optimal performance.

Kòmanse motè a:

- Pwovizyon pou gaz: Ensure the fuel tank has fresh, clean fuel and the fuel valve (if present) is open.

- Priming (si sa aplikab): If your engine has a primer bulb, press it several times until fuel is visible in the fuel line or bulb.

- Chokes: Move the choke lever to the "FULL CHOKE" position (usually indicated by a symbol or "START").

- Acct: Set the throttle to the "FAST" or "START" position.

- Kòmanse: Pull the recoil starter cord firmly or engage the electric starter.

- Ajisteman Choke: Once the engine starts and runs for a few seconds, gradually move the choke lever to the "HALF CHOKE" position, then to the "RUN" position as the engine warms up and runs smoothly.

Carburetor Adjustments (if necessary):

Your new carburetor is pre-set from the factory for general use. However, environmental factors (altitude, temperature) or specific engine conditions may require fine-tuning. Most modern carburetors have limited adjustment screws. Refer to your engine's service manual for specific adjustment procedures.

- Idle Speed Screw: Adjusts the engine's RPM at idle. Turn clockwise to increase idle speed, counter-clockwise to decrease.

- Mixture Screws (if present): These control the fuel-air mixture. Adjust in small increments (e.g., 1/8 turn) and observe engine response. Turning clockwise typically leans the mixture, counter-clockwise enriches it. Always return to factory recommended settings if unsure.

Antretyen

Antretyen regilye asire lonjevite ak pèfòmans optimal karbiratè ou ak motè ou.

- Kalite gaz: Always use fresh, clean, and appropriate fuel for your engine. Stale or contaminated fuel is a primary cause of carburetor issues. Consider using a fuel stabilizer if storing the engine for extended periods.

- Filtè gaz: Regularly inspect and replace the in-line fuel filter (if equipped) to prevent debris from reaching the carburetor.

- Filtè lè: A clogged air filter can cause the engine to run rich and affect carburetor performance. Clean or replace the air filter according to your engine's maintenance schedule.

- Netwayaj karburatè: If performance issues arise due to fuel contamination, the carburetor may need cleaning. This typically involves disassembling the fuel bowl and jets, cleaning them with carburetor cleaner, and reassembling. This procedure should only be performed by individuals familiar with carburetor mechanics.

- Depo: Before long-term storage, either run the engine until it runs out of fuel or drain the fuel system completely to prevent gum and varnish buildup in the carburetor.

Depanaj

Below are common issues and potential solutions related to carburetor performance. Always ensure basic engine components (spark plug, ignition, compression) are in good working order before troubleshooting the carburetor.

| Pwoblèm | Kòz posib | Solisyon |

|---|---|---|

| Motè pa pral kòmanse | No fuel, clogged fuel filter, clogged jet, incorrect choke setting. | Check fuel level. Replace fuel filter. Clean carburetor jets. Adjust choke. |

| Engine runs rough / Idles poorly | Dirty carburetor, incorrect idle adjustment, air leak, old fuel. | Clean carburetor. Adjust idle screw. Check for air leaks around manifold. Use fresh fuel. |

| Engine lacks power / Surges | Clogged main jet, dirty air filter, incorrect mixture setting. | Clean main jet. Clean/replace air filter. Adjust mixture screw (if applicable). |

| Fwit gaz nan karburatè a | Damaged float, worn needle valve, loose fuel bowl, damaged gasket. | Inspect/replace float and needle valve. Tighten fuel bowl screws. Replace gaskets. |

Espesifikasyon

Key specifications for the C·T·S Carburetor, Model CB-345:

- Mak: C·T·S

- Manifakti: C·T·S

- Nimewo Modèl: CB-345

- Nimewo pyès OEM yo: 15003-2475, 15003-2441

- Konpatibilite: Kawasaki FG230 engines

- Pwa atik: 8.8 ons

- Dimansyon pake: 5.91 x 5.12 x 1.97 pous

- UPC: 781108148688

- ASIN: B0DM1B4NW3

Garanti ak sipò

For information regarding warranty coverage, returns, or technical support, please refer to the seller's policy on the platform where the product was purchased. You may also contact the manufacturer, C·T·S, directly for assistance with product-specific inquiries.

For general inquiries or to visit the C·T·S store, please use the following link: C·T·S Store on Amazon